30

HOOFDSTUK 4 BEDIENING

1. Schakel de stroom in door de (wand)hoofdschakelaar te sluiten.

(De EPP-450 is niet uitgerust met een AAN/UIT-schakelaar). Het

lampje voor de hoofdvoeding gaat branden het storingslampje

gaat uit nadat het eerst heeft geknipperd.

2. De noodstopknop is uitgetrokken.

3. Selecteer de stand Panel of Remote (bedieningspaneel/afstands-

bediening).

4. Zet de HIGH/LOW-ontstekingsboogschakelaar in de juiste stand.

Als de HIGH/LOW-ontstekingsboog wordt geselecteerd met een

afstandsbediening, moet de schakelaar in de stand LOW staan.

(Raadpleeg de snijgegevens in de snijbranderhandleiding.)

5. Als u de Panelmodus gebruikt, bekijk dan de vooraf ingestelde

stroom (A) met de ACTUAL / PRESET AMPS-schakelaar (werkelijke

vs. vooraf ingestelde stroom). Wijzig de stroom totdat de gewenste

waarde op de ampèremeter verschijnt. Als u de afstandsbediening

gebruikt en de ACTUAL / PRESET AMPS-schakelaar in de stand

PRESET AMPS (vooraf ingestelde stroom) zet, zal de aanvankelijke

uitgangsstroom worden geregeld door de afstandsbediening.

6. Begin met plasmasnijden. Daarbij moet u wellicht ook andere

opties handmatig instellen, afhankelijk van het totale plasmapak-

ket.

7. Als u de Panelmodus hebt gekozen, dan moet - nadat het snijden

is begonnen - de stroom op de gewenste waarde worden inge-

steld.

8. Als het snijden of markeren niet wil starten, controleer dan de

storingslampjes. Als een storingslampje brandt, raadpleeg het

hoofdstuk Verhelpen van storingen.

Opm.:

Het storingslampje knippert als de contactgever de

eerste keer wordt ingeschakeld; dit duidt erop dat

de DC-bus normaal van stroom wordt voorzien.

4.3 Bedieningsstappen

SECTION 4 Operation

ESP 400C Plasma Power Source

ESP 400C Plasma Power SourceESP 400C Plasma Power Source

ESP 400C Plasma Power Source

4-4

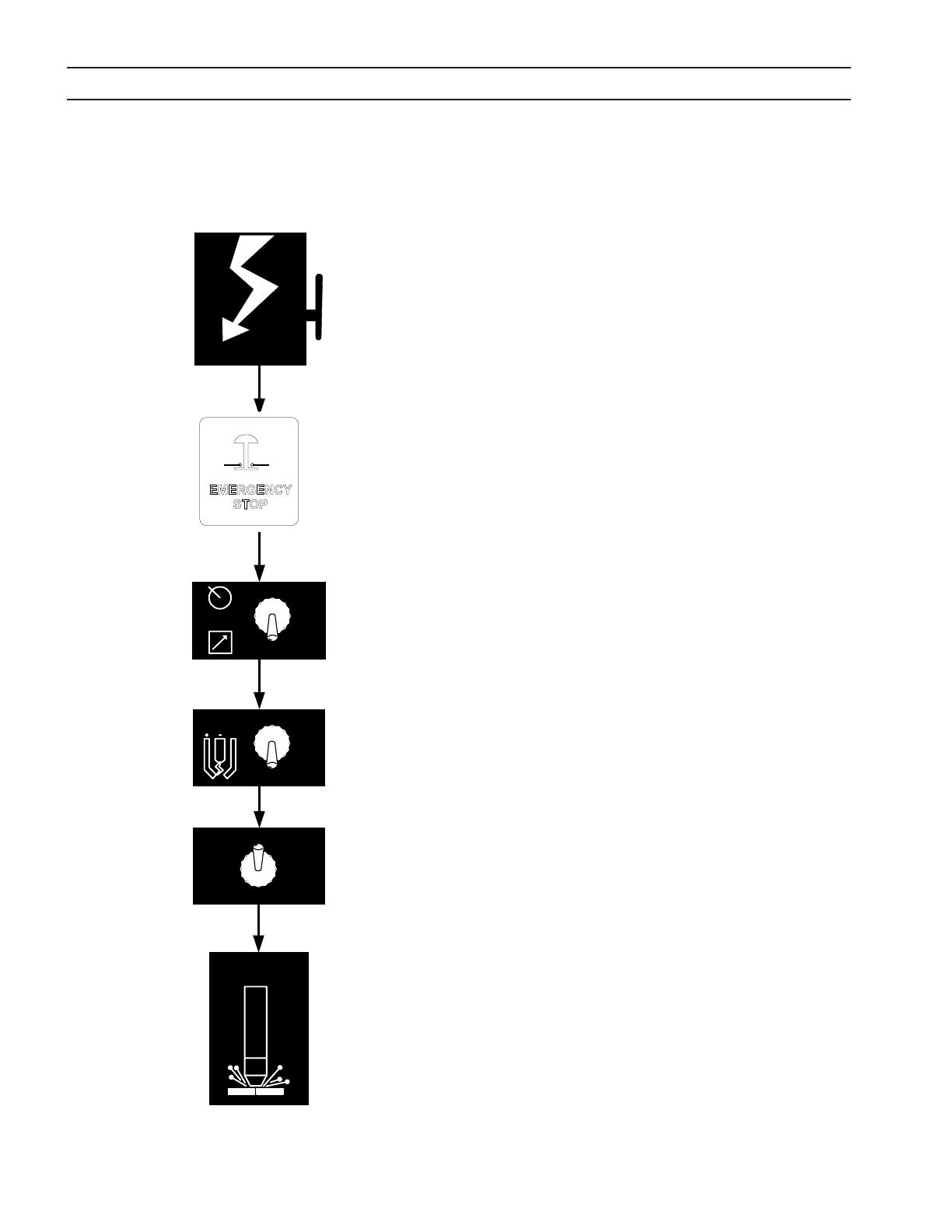

Begin

Cutting

ACTUAL AMPS

PRESET AMPS

HIGH

LOW

PILOT

ARC

PANEL

REMOTE

Apply Power

4.3 Sequence of Operation

1. Apply power by closing the line (wall) switch.

(The ESP-400C does not have an on/off

switch). The main power light will illuminate

and the fault light will flash and then go out.

2. Select the Panel/Remote setting.

3. Set pilot arc High/Low switch. (Refer to cutting

data in the torch manual.)

4. If using panel mode, view preset amps with the

ACTUAL/PRESET AMPS switch. Adjust current

until the approximate desired value is shown on

the ammeter.

5. Begin plasma cutting operation. This may

include manually setting up other options,

depending on the total plasma package.

6. If using panel mode, after cutting has begun,

adjust current to desired amount.

7. Check for fault light. If a fault light illuminates,

refer to troubleshooting section.

Note: The fault light flashes when the contactor is

Note: The fault light flashes when the contactor isNote: The fault light flashes when the contactor is

Note: The fault light flashes when the contactor is

first turned on signifying the DC Bus powered up

first turned on signifying the DC Bus powered upfirst turned on signifying the DC Bus powered up

first turned on signifying the DC Bus powered up

normally.

normally.normally.

normally.

4.4 Arc Initiation Settings

The time to achieve full current can be adjusted to

suit your particular system. This feature uses 50%

of the cutting current to start, dwell and then

gradually (less than a second) achieve full current.

The ESP-400C is factory shipped with this feature

enabled. The default settings are:

Minimum Start Current 40A

Start Current 50% of cut current

Timing to achieve full current 800 msec

Dwell Time 50 msec

SECTION 4 Operation

ESP 400C Plasma Power Source

ESP 400C Plasma Power SourceESP 400C Plasma Power Source

ESP 400C Plasma Power Source

4-4

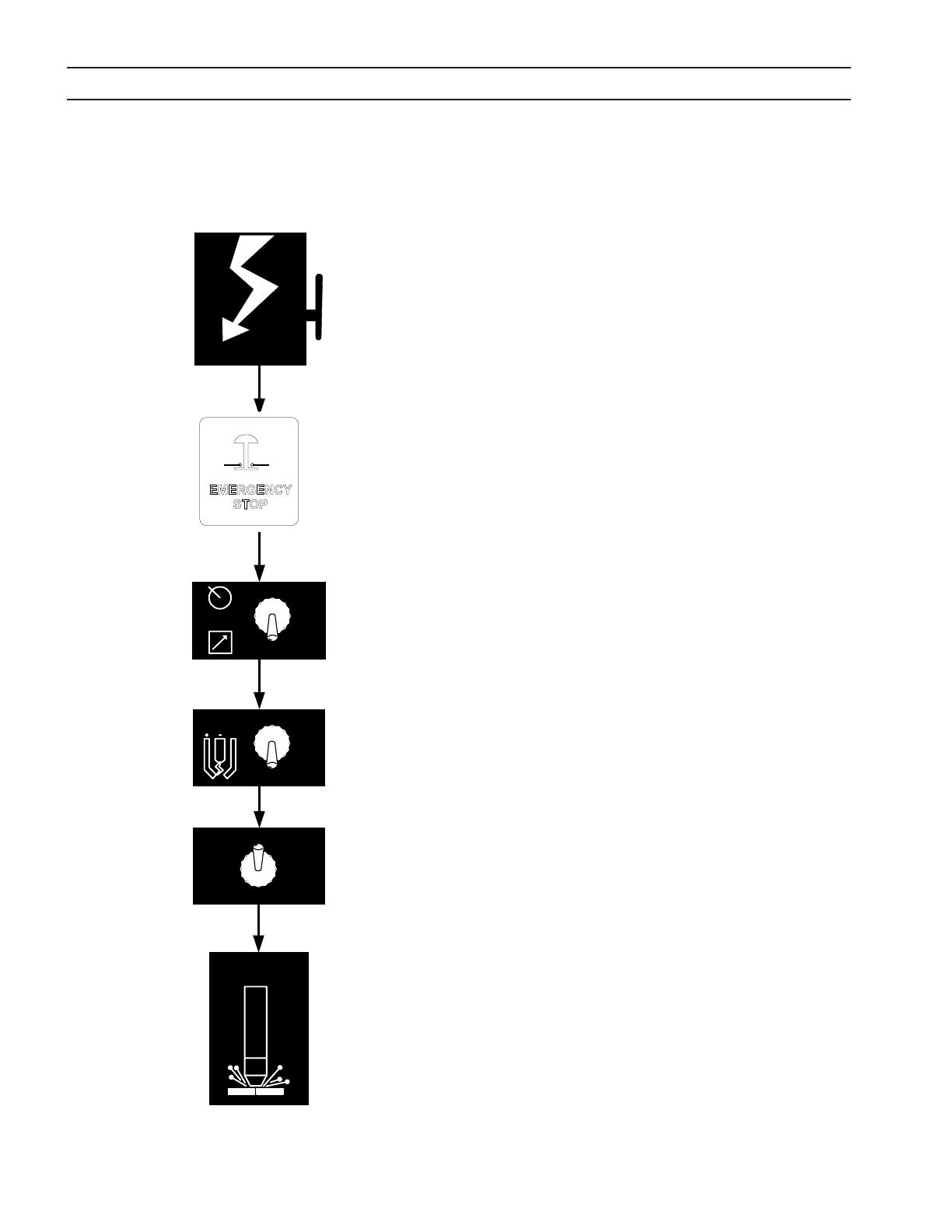

Begin

Cutting

ACTUAL AMPS

PRESET AMPS

HIGH

LOW

PILOT

ARC

PANEL

REMOTE

Apply Power

4.3 Sequence of Operation

1. Apply power by closing the line (wall) switch.

(The ESP-400C does not have an on/off

switch). The main power light will illuminate

and the fault light will flash and then go out.

2. Select the Panel/Remote setting.

3. Set pilot arc High/Low switch. (Refer to cutting

data in the torch manual.)

4. If using panel mode, view preset amps with the

ACTUAL/PRESET AMPS switch. Adjust current

until the approximate desired value is shown on

the ammeter.

5. Begin plasma cutting operation. This may

include manually setting up other options,

depending on the total plasma package.

6. If using panel mode, after cutting has begun,

adjust current to desired amount.

7. Check for fault light. If a fault light illuminates,

refer to troubleshooting section.

Note: The fault light flashes when the contactor is

Note: The fault light flashes when the contactor isNote: The fault light flashes when the contactor is

Note: The fault light flashes when the contactor is

first turned on signifying the DC Bus powered up

first turned on signifying the DC Bus powered upfirst turned on signifying the DC Bus powered up

first turned on signifying the DC Bus powered up

normally.

normally.normally.

normally.

4.4 Arc Initiation Settings

The time to achieve full current can be adjusted to

suit your particular system. This feature uses 50%

of the cutting current to start, dwell and then

gradually (less than a second) achieve full current.

The ESP-400C is factory shipped with this feature

enabled. The default settings are:

Minimum Start Current 40A

Start Current 50% of cut current

Timing to achieve full current 800 msec

Dwell Time 50 msec